RPI – REFLOW PROCESS INDEX

www.kicthermal.com

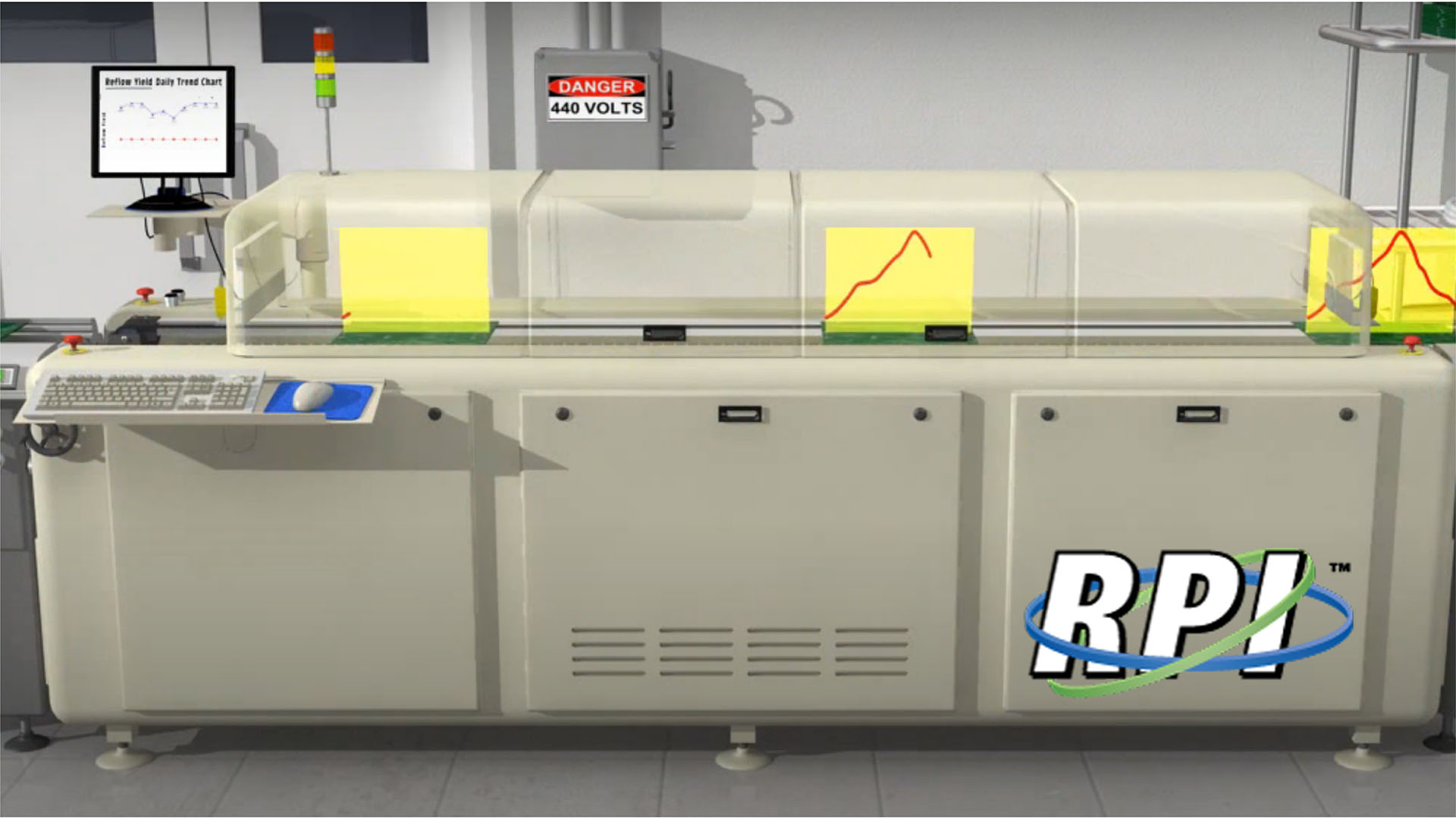

A reflow oven is a very busy machine striving to control multiple variables while heating and cooling PCBs. The purpose of the oven, however, is to:

A reflow oven is a very busy machine striving to control multiple variables while heating and cooling PCBs. The purpose of the oven, however, is to:

- Create a specific PCB profile

- Maintain required throughput

- The RPI utilizes embedded sensors for heat and conveyor speed to automatically measure and display the following information:

- PCB profile

- Profile’s “fit” to the process window

- Continuously displayed production details (Product name and lot ID, Oven name, Production date and time stamp etc)

- PCB process traceability

- Statistics of defects and process yields

It’s provided with the following software:

KIC AUTOFOCUS and KIC AUTOFOCUS POWER – to eliminate the need to “guess” at an initial oven recipe, and instead calculates the ideal oven recipe.

KIC NAVIGATOR and KIC NAVIGATOR POWER – to identify the single best oven setup based on your choice of 3 optimization criteria:

KIC AUTOFOCUS and KIC AUTOFOCUS POWER – to eliminate the need to “guess” at an initial oven recipe, and instead calculates the ideal oven recipe.

KIC NAVIGATOR and KIC NAVIGATOR POWER – to identify the single best oven setup based on your choice of 3 optimization criteria:

- Center of the Process Window – PWI – (Process Window Index)

- Maximum Conveyor Speed

- Minimum Electricity Use

FEATURES:

- Process traceability for each PCB

- Management data for reflow quality and throughput

- Reduced production cost

- Measuring process quality — independent of equipment, personnel and location

- Automated continuous profiling

LASER CUT

CONSUMABLES

SMT MACHINES

EQUIPMENTS

TECNOLAB - Equipments

TAGARNO – Digital microscope

PDR – Rework system

HOVER DAVIS – Feeder

EMT – Auto Dry Cabinet

KIC – Smart Profiler

PUREX – extraction system

MODI – Incoming relabeling station

ARCADIA - Sistemi di Gestione Intelligente